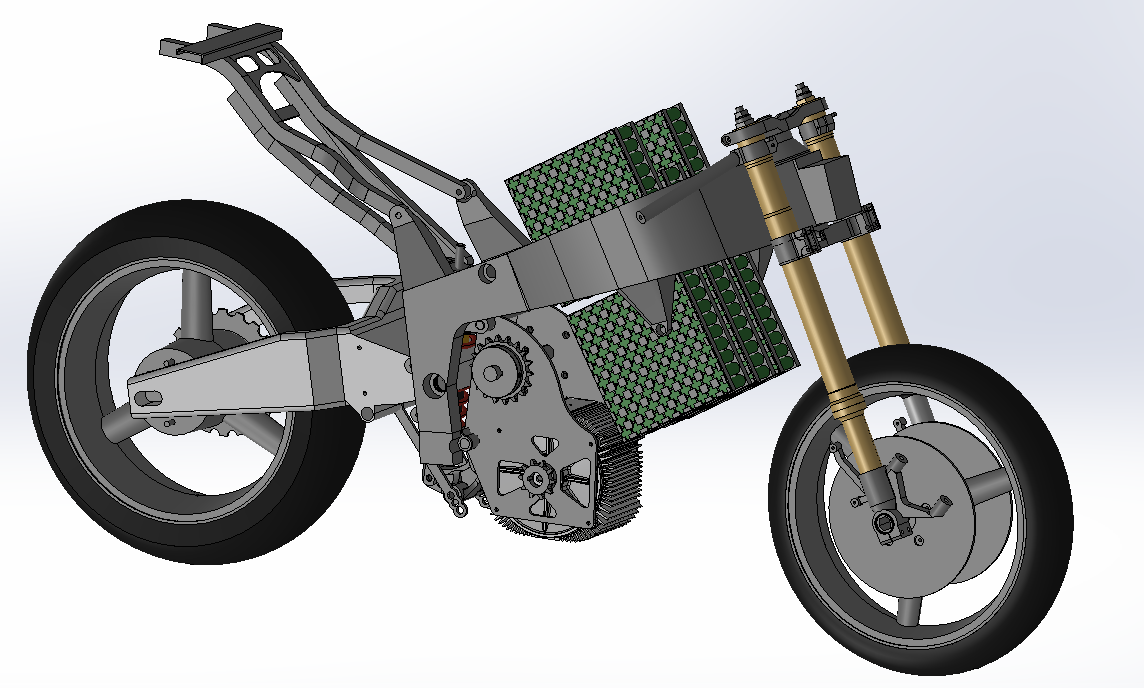

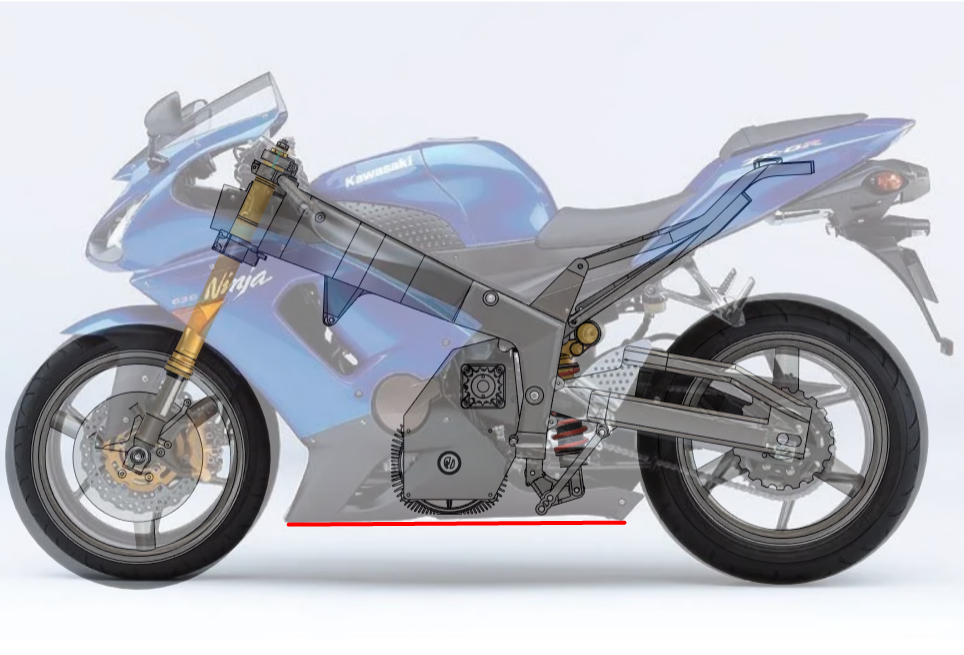

As previously stated, our team wanted to build a high-performance superbike for AHRMA Formula Lightning. Since this is our team's first bike, our main goal was to build a functional bike capable of reaching a top speed over 100 mph. To the left is the frame we're building off of: a 2005 Kawasaki Ninja ZX-6R

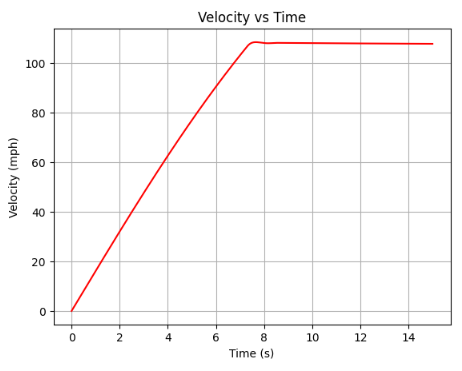

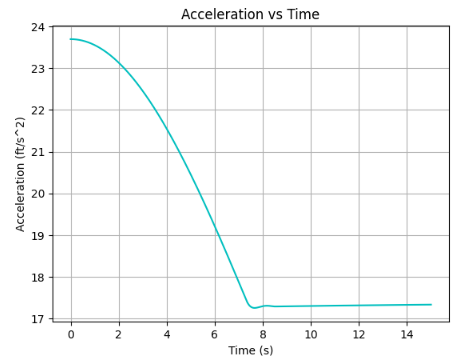

I built a Python script that models the different forces acting on the bike during movement. The forces considered were: drag, rolling resistance, wheel force, and friction (leading to efficiency losses). Using this model, I created a differential equation that could be solved to obtain the position vs time graph. Taking the first and second derivatives would yield the velocity and acceleration graph, respectively.

By simulating different gear ratios, I was able to determine the ideal output torque. Taking into account our tire's estimated coefficient of friction and ideal slip ratio (tires operate best at a certain slip ratio, typically around 10%-20%), I was able to determine the ideal torque to be around 575 Nm. This allows us to achieve strong acceleration, prevent excessive slippage, and achieve our goal of 100+ mph. Our team will be using a ZF75-7 motor, which has a peak torque of 110 Nm and approximately 60 horsepower. This means that a 5.2 : 1 gear ratio is needed

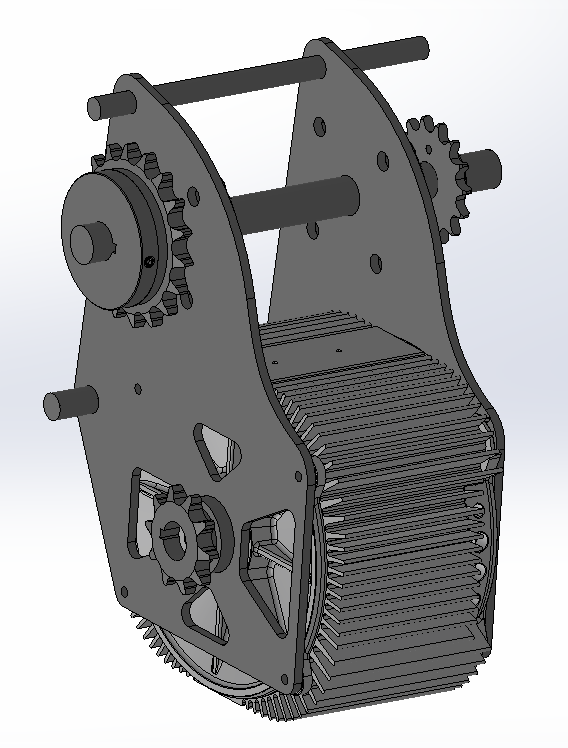

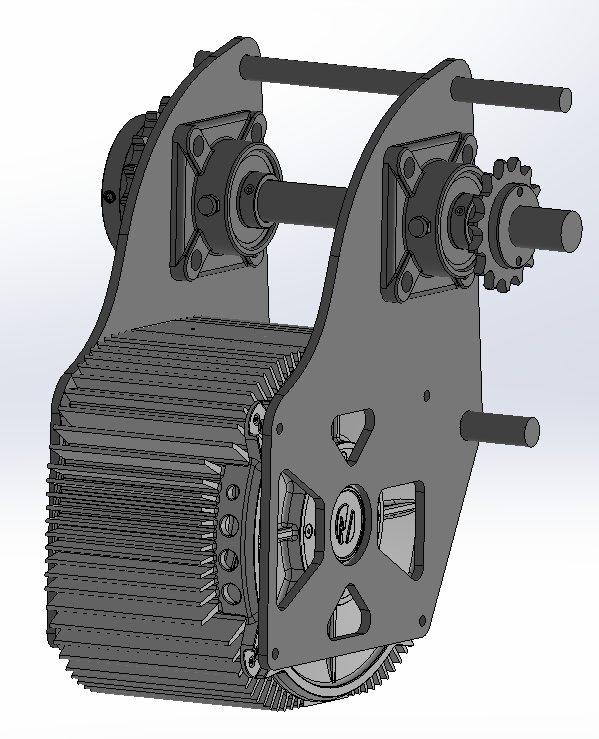

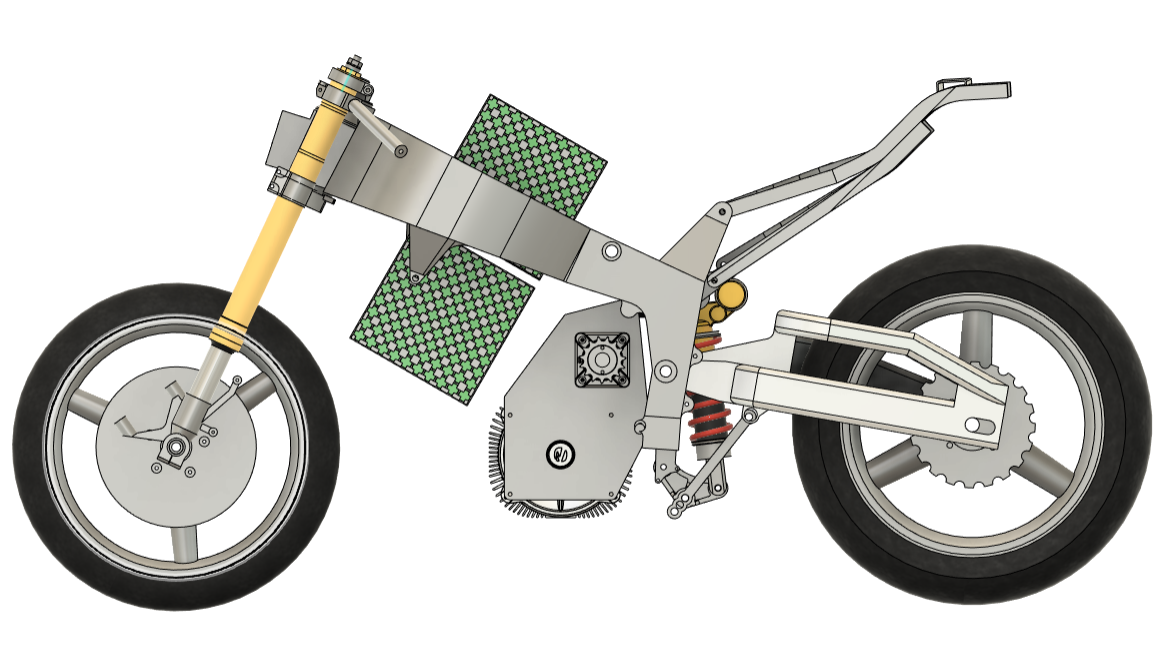

Given the required 5.2 : 1 reduction, using a single stage drivetrain isn't feasible due to how excessively large the rear sprocket would need to be. Therefore, I decided on a two-stage system with an 18:10 ratio between the motor and jackshaft and a 43:15 ratio between the jackshaft and wheel. This ultimately left us with a 5.16:1 reduction, very close to ideal.

The primary design challenge was the lack of packaging space. I needed to avoid interference with the battery and suspension while maintaining structural integrity and optimal anti-squat geometry (more on this in the next section).

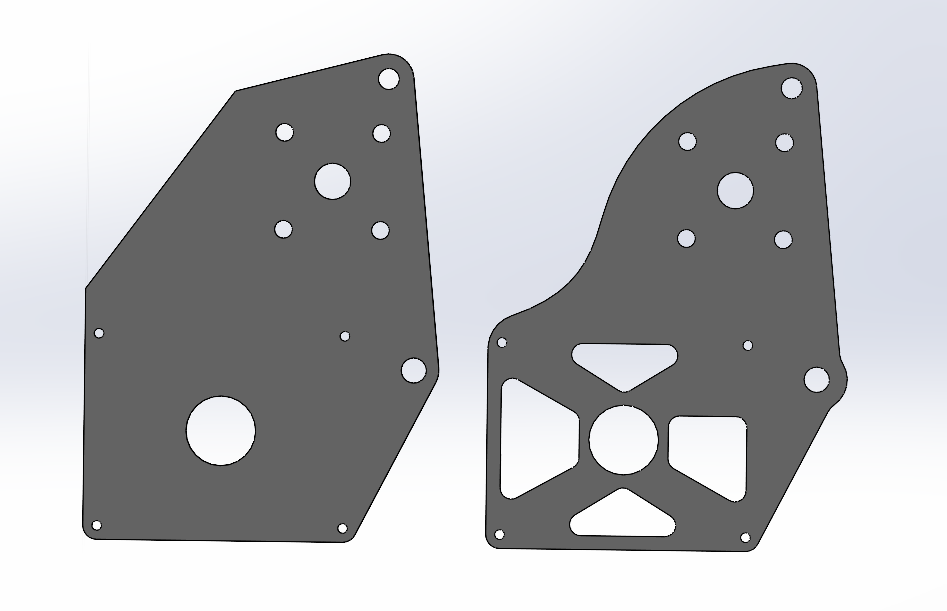

The final configuration I came up with mounts the motor as low as possible, just slightly above the bottom fairing of the stock ZX-6R. This leaves more room for the battery and BMS and makes it easier to direct airflow to the motor for cooling purposes later on. The jackshaft location is parameterized relative to the suspension pivot for easy anti-squat tuning. The material I selected for the motor mounts was 1/4" sheet metal due to its low cost and ease of manufacturing. With free access to our school's waterjet cutter, I'm able to quickly design different prototypes at a low cost.

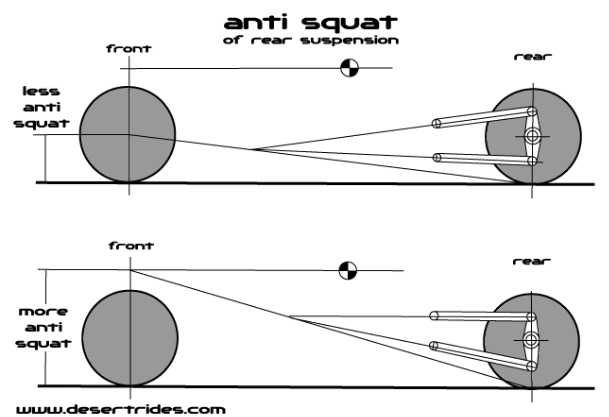

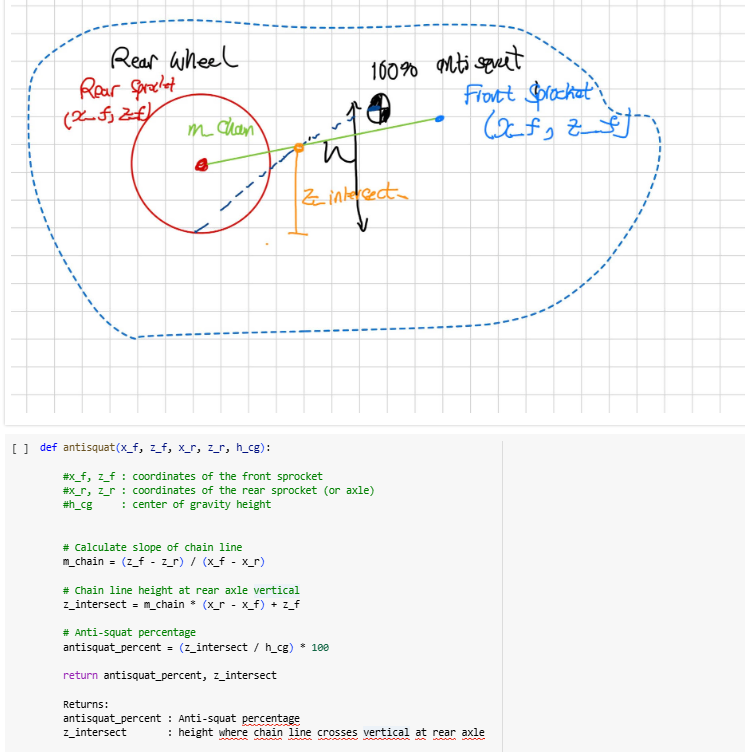

Anti-squat is a suspension characteristic that determines how much the rear suspension compresses (or "squats") under acceleration. Anti-squat is typically expressed as a percentage where 100% means that the suspension stays perfectly still under acceleration. Anti-squat percentages <100% (sometimes known as pro-squat) mean that the suspension will compress during acceleration. The physics behind how this works can be a difficult concept to wrap your head around, but tuning anti-squat properly is imperative for performance. Too much anti-squat and the bike can spin out and lose traction. Too little anti-squat and you lose power and the ability to corner efficiently.

Since the bike is currently in its early stages, it's hard to determine what the "neutral" position of the suspension will be with the rider on the bike. For now, a rough estimate will be used, and the jackshaft position can be adjusted later during testing to get us closer to our ideal value (stay tuned for that). Being able to easily prototype and change the motor mount geometry is one of the key reasons I chose to use sheet metal.

However, one of the factors that I can calculate right now is what our ideal anti-squat percentage will be. While I can't disclose the exact number, I was able to build a simple calculator in Python that would help us determine where I would need to place our jackshaft.

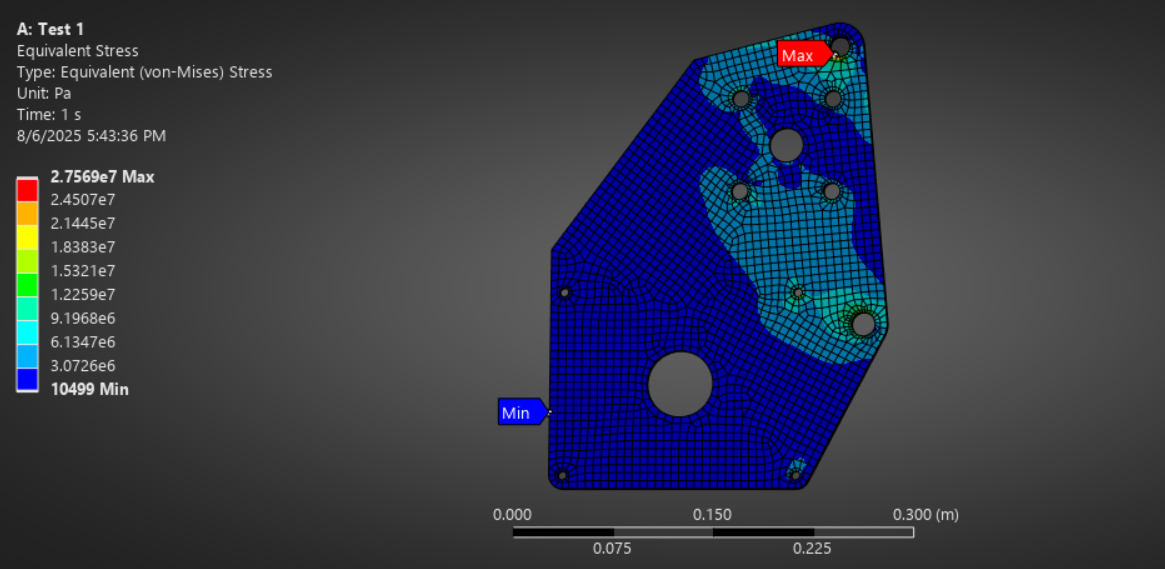

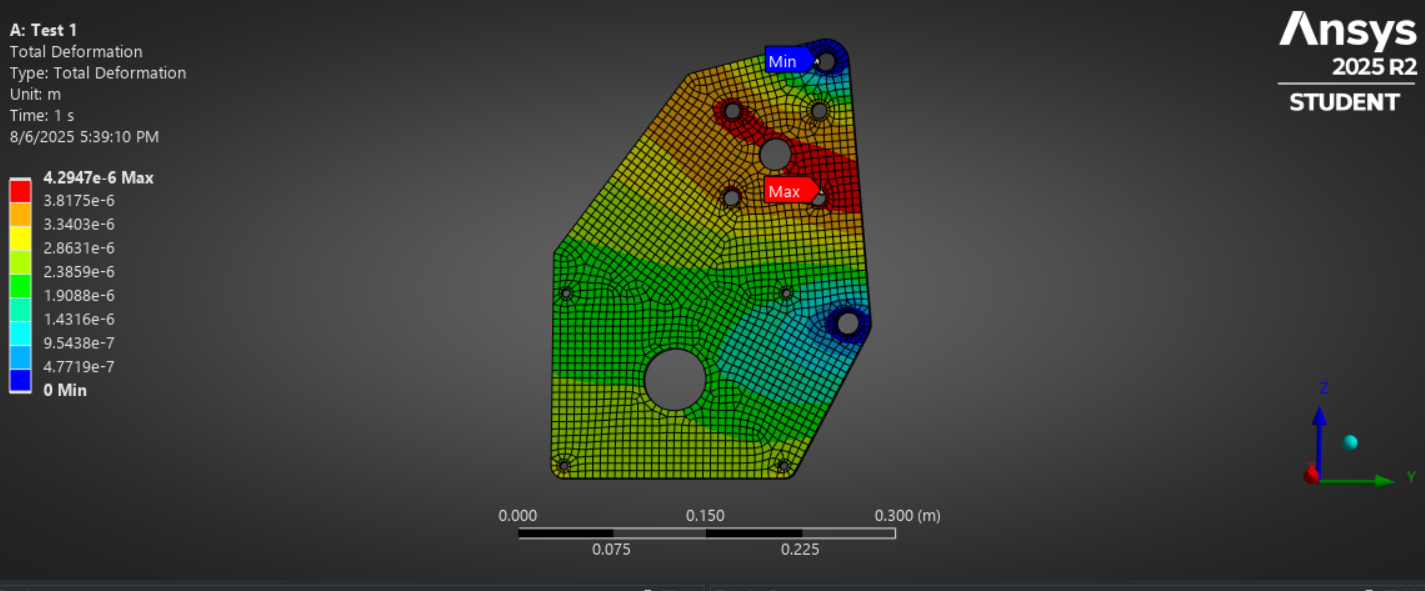

I wanted to quickly make sure that the motor mounting pieces could safely handle the forces during drive, so I ran an FEA simulation in ANSYS Mechanical. Based on the results, the maximum equivalent (Von Mises) stress that the motor mount undergoes is 2.7569 × 107 Pa or 27.57 MPa. The yield stress of A36 Steel (the type of steel in our sheet metal plates) is around 250 MPa, giving us a safety factor of around 9. From the total deformation results, the maximum deformation is 0.004 mm, meaning the mount behaves as essentially rigid under load. This means that I can remove material while staying well within the desired safety factor of 3.

I decided to remove material around low stress around and add material in higher stress areas. After a couple of iterations, I achieved a design I liked. It has a 26% weight reduction from the original while staying well within our desired safety factors. While I'm sure further weight reductions are possible, the marginal benefit didn't seem worth the additional effort, which could be better directed elsewhere.

Stay tuned for building, testing, and a CFD project coming soon!